定制精密失蜡铸造零件制造 A356 铝不锈钢投资铸造铸造厂

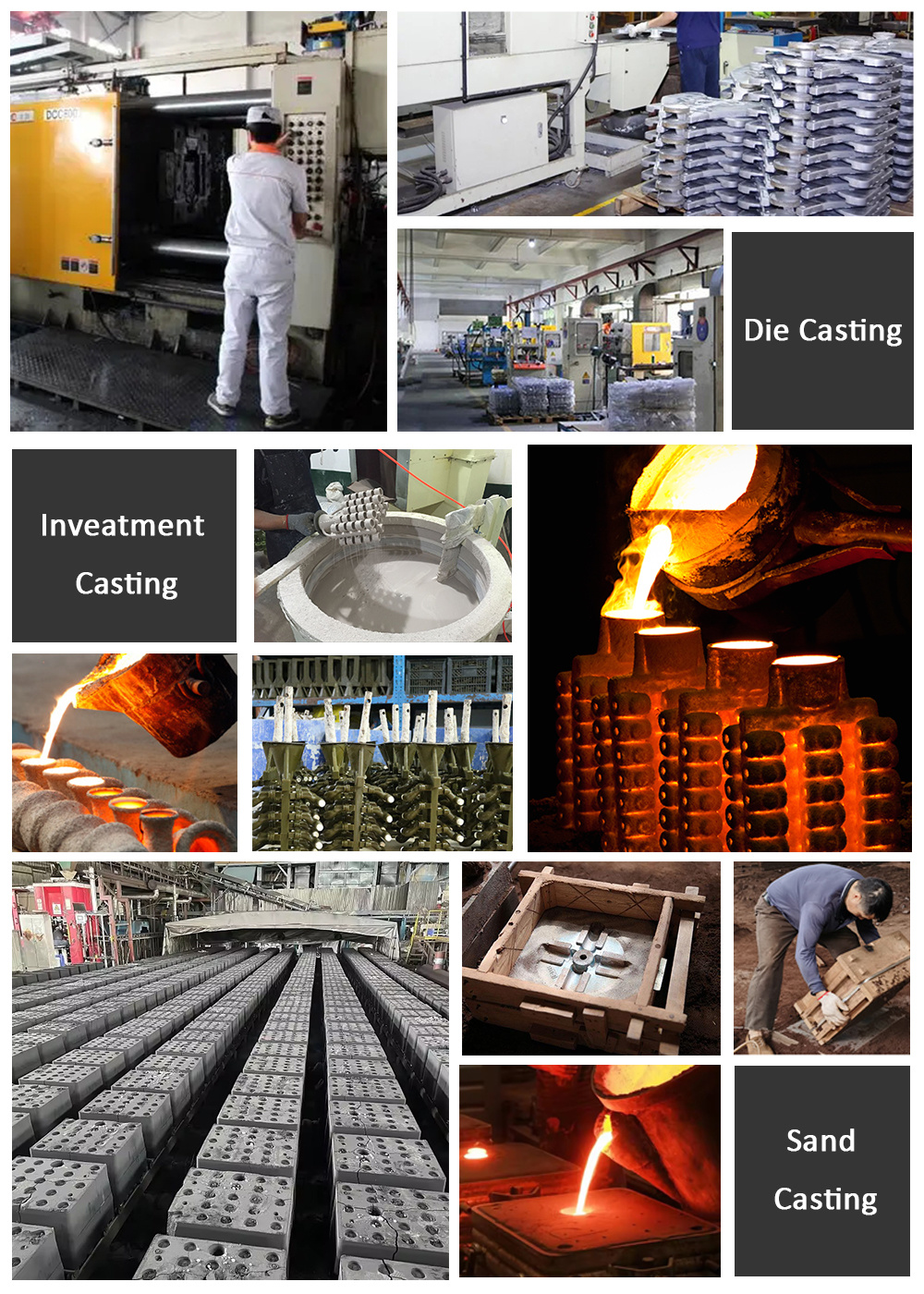

我们的工厂专注于生产不同金属材料的压铸件、铸件和砂铸件。我们经验丰富的工程师和技术团队能够处理复杂的模具设计、工艺优化和质量问题。成熟的生产线确保高效生产和高质量产品。从原材料采购到成品交付的严格质量控制确保每个环节都符合客户要求和行业标准。凭借灵活的生产能力,我们能够快速响应客户需求,提供定制解决方案并缩短交货周期。

类别:

家居配件

关键词: 压铸

我要咨询

产品描述

| Product name | Custom Precision Lost Wax Casting Parts Fabrication A356 Aluminum Stainless Steel Investment Casting Foundry |

| Quotation | According to your drawing(size, material, thickness, processing content, and required technology, etc) |

| Tolerance | +/-0.01mm |

| Materials Avaiable | Aluminum alloy ADC12, ADC10, A360, A380, A356 Magnesium Alloy AZ91D, AM60B Zinc alloy ZA3#, ZA5#, ZA8# Stainless steel, Grey Iron, Steel, Brass, Bronze (Can be customized as customers' requirements) |

| Surface Treatment | Electroplating/Polishing/Powder Coating/Sandblasting/Metal Brushing/Anodizing/Electrophoresis/Shot Blasting/Phosphating/Baking Paint |

| Drawing Formats | IGES, STEP, AutoCAD, Solidworks, STL, PTC Creo, DWG, PDF, etc |

| Application | Furniture, Industry fittings and Construction and Decoration, etc. |

1. Die Casting

1. Die Casting

- High precision surface finish:Die casting produces complex shapes and thin walls.

- Efficient production:Ideal for high-volume manufacturing with automated processes.

- Limited to low-melting-point alloys:Best suited for aluminum, zinc, and magnesium.

- High initial costs:Requires significant investment in molds and equipment.

- 2. Investment Casting

- Exceptional precision surface finish:Achieves fine details and complex geometries.

- Versatile material options:Supports a wide range of metals, including stainless steel and superalloys.

- Broad size range:Suitable for both little and large parts.

- Higher costs:The process is more intricate, making it suitable for medium to low-volume production.

3. Sand Casting

- Cost-effective:Uses inexpensive mold materials, ideal for single or low-volume production.

- Flexible and adaptable:Can produce parts of almost any size and shape.

- Suitable for large parts:Commonly used for heavy machinery components.

- Rougher surface finish:May require additional machining.

- Limited dimensional accuracy:Not as precise as die casting or investment casting.

Cooperation process

1. Demand confirmation:Communicate with customers to clarify product specifications, material selection and special requirements.

2.Design and engineering:Customers provide design drawings and develop detailed production process plans.

3. Mold manufacturing:According to the design plan, molds are manufactured to ensure mold quality and service life.

4. Trial production and verification:Samples production, conduct comprehensive quality inspections and customer confirmation, and adjust the process based on feedback.

5. Mass production:Carry out large-scale production according to the optimized process flow, and strictly control the quality of each link.

6. Post-processing:Carry out necessary cleaning, heat treatment and surface treatment to improve product performance and appearance.

7. Quality inspection:Carry out comprehensive inspection of finished products to ensure that they meet customer requirements and industry standards.

8. Packaging and delivery:Packaging according to customer needs, and arrange logistics distribution to ensure safe and timely delivery.

Henan Yuanfei is one famous company in China which specialized in various metal casting products with over 10 years experience, located in China.It covers a comprehensive range of sand casting, investment casting, die casting and widely used in Agriculture machinery, Motor Vehicle, Architecture,Railway and Engineering We have a complete line of mold making, casting production, machining and assembly to meet customer requirements for finished parts. For our customers we have designed and manufactured over hundreds sets of moulds these years. Most of our products have exported to USA, Germany, Italy, U.K., Belgium , Finland and so on.

相关产品

你有什么问题吗?

我们将在一个工作日内联系您。请注意您的电子邮件。